Fuel Injectors (Petrol)

What technicians need to know when servicing /replacing petrol fuel injectors on the various injection systems.

Fuel injection systems have evolved over the years to the latest stratified direct injection systems that is necessary to service the current strict emission requirements.

Earlier vehicles utilized a variety of injection systems that varied in appearance and operation.

Most vehicles on our roads utilise the Multi point port injection and the Direct injection systems on later vehicles and are the more commonly worked on systems.

The Multipoint Port Injection System - Technical requirements.

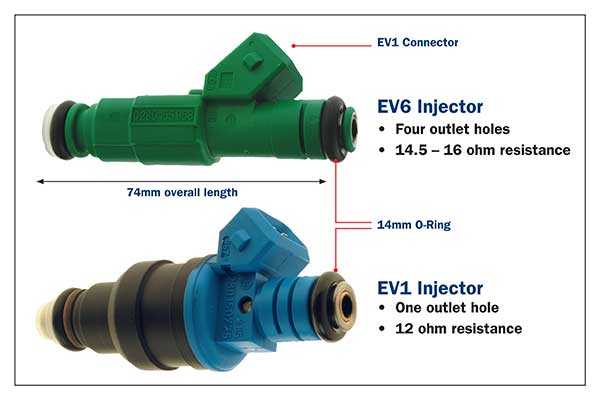

- These injectors may be either high or low impedance.

Note: many injectors look similar but cannot be substituted if the impedance is incorrect. Current control is required for correct injector operation and to ensure no circuit damage is created. Replacing a high impedance injector with a low impedance unit will increase the current and possibly cause damage to the ECU.

- Injector fuel flows may vary slightly or dramatically, depending on the application so it is essential that the correct fuel injector unit is fitted to ensure smooth engine operation and correct emission levels.

- Injector flow rates on performance or off-road use will vary depending on the engine modifications carried out.

- The multipoint injection system may utilise either Pintle type or Multi hole injector types.

The spray pattern and angles will vary amongst the types and it is not recommended to mix the injectors fitted to an engine even though the flow rates may be similar.

Fuel injector operating methods utilised by the ECU.

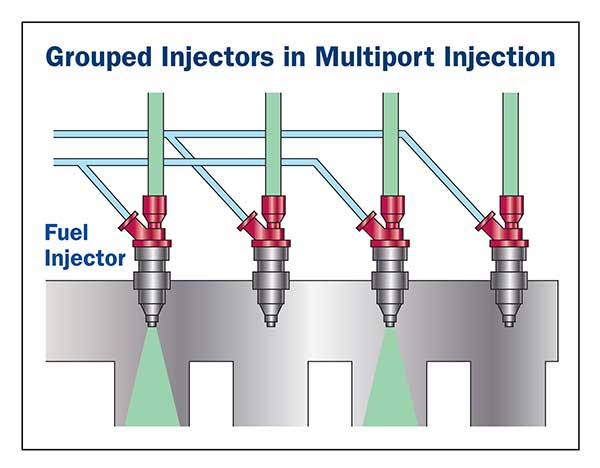

Grouped Injection (Early port injection only).

This system generally activates half of the number of the Injectors alternatively in two banks. A faulty injector driver in the ECU will cause all injectors in that bank to malfunction causing multiple misfiring.

Sequential Injection (Later port and Direct Injection)

This system allows the injectors to activate individually in a firing order sequence.

A greater accuracy of fuel control is created and a faulty Injector driver in the ECU would cause one injector only to be affected.

Note: Typically, if a specific cylinder ignition coil spark is weak, the ECU may prevent injection on that cylinder only - to reduce unburnt fuel reaching the catalytic converter and causing potential damage.

Direct Injection

As more restraints are placed on the vehicle emissions, manufacturers have utilised the “Direct petrol injection system”

Injectors suitable for this system vary dramatically with the port injection requirements.

Typically:

- Extreme fuel pressures

- High operating voltages.

- Extreme operating temperatures at the injector tips.

Due to the operating conditions placed on these injectors, it is important that they perform without any malfunction as performance and emission levels are affected dramatically.

Injector Servicing

Carbon and wax build-up around the injector tips and foreign particles in the fuel rail and lines create a need for regular injector servicing. It is important that only quality components are utilized for these procedures to prevent premature vacuum, air or fuel leaks.

njector Diagnosis Precautions.

When diagnosing a misfire or suspected injector malfunction, it is important to determine where the fault possibility may lie.

That is - The injector relies on:

- Correct fuel pressure and flow.

- Correct activation from the ECU. “Injection duration” monitored by a suitable scanner or oscilloscope can quickly identify if the injector ON period is correct.

- No internal injector fuel restrictions. (Dirty/blocked injectors).

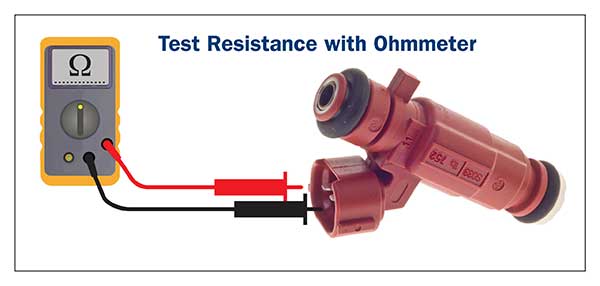

- Any harness /wiring problems causing intermittent or hard faults.